Ready for the next generation of energy

Transforming Bahrain’s energy future

The Kingdom of Bahrain’s energy landscape is changing. The way forward is global, collaborative, inclusive and our success will be driven by our innovative spirit and industry-leading expertise.

As a progressive, future-ready energy company, Bapco Energies is actively investing in the diversification of the national energy infrastructure, growing the industry-leading expertise of our people and building on our strategic global partnerships.

To power the next generation

Continuously monitoring the combined impact across the Bapco Energies business is critical to the management of our long-term strategy.

The switch is not instant and the transition to renewable energy must be made consciously and sustainably to secure the next generation of our industry.

From processes to technology and investment, we partner with the best in every field to amplify the innovative spirit and industry-leading experience of our people.

Incremental strategic targets for our company are carefully aligned with #TeamBahrain’s objectives for the next generation of Bahrain, our part in the international energy landscape and the national objective of achieving Economic Vision 2030.

Our success is the combined success of our employees, suppliers, and customers. We actively support free-flowing communication and provide platforms that encourage new methods and thinking across the Bapco Energies business.

To develop, manage and build our nation’s portfolio of energy companies and infrastructure, we invest with ambition, care and keep net zero front of mind.

We actively promote excellence in everything we do and are confident this will only help us achieve Bahrain’s climate targets.

A powerful vision from His Highness Shaikh Nasser bin Hamad Al Khalifa, His Majesty’s Representative for Humanitarian Works and Youth Affairs is the Chairman of the Bapco Energies’ Board.

Speak Up with Confidence: Promoting Integrity and Accountability

We are committed to maintaining the highest level of corporate governance whilst streamlining integrated control systems to deter, detect, and prevent improper or illegal activities.

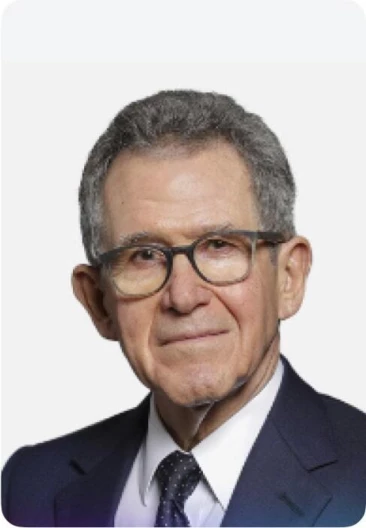

His Highness Shaikh Nasser bin Hamad Al Khalifa, His Majesty’s Representative for Humanitarian Works and Youth Affairs and Chairman of Bapco Energies

Under the leadership of His Highness Shaikh Nasser bin Hamad Al Khalifa the Chairman, the Bapco Energies Board and Management are leading the Company’s transformation and are committed to maintaining the highest levels of corporate governance.

Bapco Refining offers one of the highest-quality refining capabilities in the Middle East, including the Bapco Modernization Programme (BMP). BMP is the largest energy investment in the history of Bahrain.

Bapco Upstream is the steward of the Bahrain Field and is responsible for the execution of all upstream operations across the Kingdom of Bahrain. It focusses on exploration, field development, production and the distribution of oil and gas.

Bapco Gas promotes oil production from the Bahrain Oil field, treats process-associated gas and the extraction of marketing products, propane, butane and naphtha, and their supply to local industries with surplus gas.

Bapco Gas Expansion Company focuses on the processing, storage and distribution of Propane, Butane and Naphtha from the Bahrain Oil Field’s and off-gas from Bapco Refining.

Bapco Tazweed manages the national infrastructure of service stations, their services and is the national destination of choice for fuelling and convenience.

Bapco Air Fueling handles all aviation refueling at Bahrain International Airport.

Bapco Gasoline Blending processes and supplies gasoline to meet both the Bahrain domestic demand and our supply to the import and export markets.

Bapco Lube Base Oil Company produces Very High Viscosity Index (VHVI), Group III Base Oils, including the BAPbase® base oils brand.

The Bahrain LNG terminal includes a liquefied natural gas receiving, storage and regasification facility located offshore Hidd, with gas conditioning and send-out plant on the Khalifa Bin Salman Port (KBSP) Causeway.

BAC Jet Fuel (BJFCO) manages the network refueling infrastructure at Bahrain International Airport.

GPIC is a joint venture equally owned by Bapco Energies, SABIC Agri-nutrient Investments, and Petrochemical Industries Co. GPIC uses natural gas that is readily available in Bahrain as a feedstock for the production of the following petrochemical products: ammonia, urea and methanol.

ASRY is the Arabian Gulf's leading maritime repair, fabrication, and engineering facility for ships, rigs, and marine assets.

Bapco Energies is the consolidation of the Kingdom of Bahrain’s energy infrastructure and operations, and the alignment around a common purpose.

With a legacy built on over 90 years of discovery, innovation and success renowned across the global energy sector, Bapco Energies and its predecessors have played an integral role in the Kingdom’s international achievements. Bapco Energies continues to fulfil the Kingdom’s growing demand for energy and support economic growth in line with the Economic Vision 2030.

“Our ultimate aim is the evolution of the Kingdom of Bahrain’s energy sector in its entirety and that involves more than just us. We’ll make this shift the catalyst for economic growth to realise the aspirations of His Majesty King Hamad bin Isa Al Khalifa and His Royal Highness Prince Salman bin Hamad Al Khalifa, Crown Prince and Prime Minister.”

His Highness Shaikh Nasser bin Hamad Al Khalifa His Majesty’s Representative for Humanitarian Works and Youth Affairs and Chairman of Bapco Energies

Get in touch with us and be a part of the Kingdom’s energy transformation.

-

Email

-

Telephone

-

LocationView location on maps

Bapco Energies

GFH Tower,

13th Floor Building No. 1411,

Road No. 4626, Block 346,

Bahrain Financial Harbour District,

Sea Front / Manama Kingdom of Bahrain.